Auto rally parts, designed for rugged conditions, require regular inspections and replacements to maintain optimal performance. Intense racing can lead to brake pad and rotor wear, affecting braking efficiency, while dust in air filters restricts airflow, impacting fuel efficiency and suspension components. Modern diagnostic tools like OBD scanners aid in identifying faulty components. Prompt action on wear and tear issues, using high-quality compatible parts, prevents further damage, ensuring peak auto rally parts condition for superior race results.

Unsure where to begin when troubleshooting issues with your auto rally parts? This comprehensive guide is your go-to resource. We’ll first unravel the most common causes of auto rally parts failures, equipping you with knowledge. Next, we’ll introduce diagnostic tools that streamline the process. Finally, we’ll outline clear steps for replacing or repairing damaged components, ensuring you’re prepared to tackle any challenge.

- Understanding Common Auto Rally Parts Failures

- Diagnostic Tools for Efficient Troubleshooting

- Steps to Replace or Repair Damaged Components

Understanding Common Auto Rally Parts Failures

Auto rally parts are designed to withstand extreme conditions, but like any high-performance components, they can fail over time. Understanding common failure points is crucial for effective troubleshooting. One of the most frequent issues with auto rally parts is related to performance brakes. Wear and tear from intense racing or harsh driving conditions can cause brake pads and rotors to deteriorate, leading to reduced braking efficiency and increased stopping distances. Regular inspection and timely replacement of these critical components are essential to ensure driver safety.

Another area of concern is the air filter kits. Dust, debris, and small particles can accumulate within the air filters, restricting airflow to the engine. This not only reduces fuel efficiency but can also lead to premature wear on various suspension components. Regular cleaning or replacement of air filters can help maintain optimal engine performance and prolong the life of other high-stress rally parts.

Diagnostic Tools for Efficient Troubleshooting

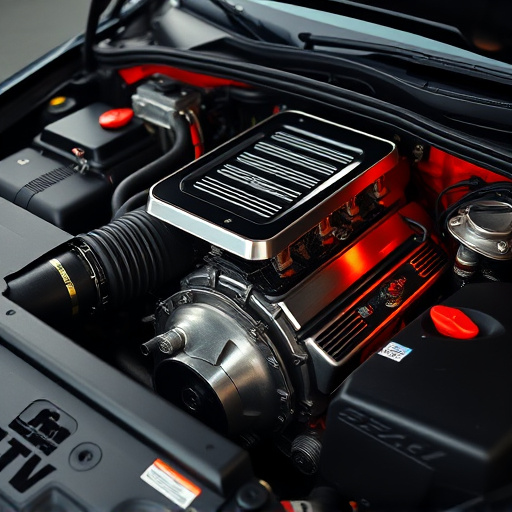

When it comes to troubleshooting issues with auto rally parts, having the right diagnostic tools can significantly streamline the process. Modern vehicles are equipped with advanced onboard diagnostics (OBD) systems that provide a wealth of information about engine performance and potential problems. Familiarize yourself with your car’s OBD system and invest in a code scanner tool to read and interpret error codes. This will help you quickly identify faulty auto rally parts, whether it’s a problem with the brake rotors, exhaust tips, or other critical components.

Additionally, consider utilizing specialized tools designed for specific tasks like brake inspections. These tools can detect even subtle issues that might be missed by basic diagnostic equipment. By combining these advanced tools with your knowledge of auto rally parts and their functions, you’ll be able to efficiently troubleshoot and resolve problems, ensuring your vehicle’s performance and safety on the racetrack.

Steps to Replace or Repair Damaged Components

When dealing with damaged auto rally parts, identifying the issue and replacing or repairing them is crucial for maintaining optimal performance during races. Start by inspecting the vehicle thoroughly to locate any signs of wear and tear. Pay close attention to components like the air intake systems and intake components, as they are often susceptible to damage due to rugged terrain. If a part is beyond repair, it’s best to replace it entirely.

For repairs, focus on areas such as coils in coilover kits, which can be adjusted or replaced if damaged. Ensure all replacement parts are of high quality and compatible with your rally car model. Regular maintenance and prompt attention to issues will help prevent further damage, keeping your auto rally parts in top shape for optimal performance during competitive events.

Troubleshooting and repairing auto rally parts can be a complex process, but with the right knowledge and tools, it becomes more manageable. By understanding common failures, utilizing diagnostic tools effectively, and following structured steps for replacement or repair, rally enthusiasts can significantly reduce downtime and keep their vehicles on the track. Regular maintenance and prompt action when issues arise are key to ensuring reliable performance in the demanding world of auto rallies.